-

Recent Posts

-

Expert Insights: What to Look for When Selecting an Extension Builder in London

February 25, 2024 By adminExpanding your living space can be an exciting prospect, offering the potential to create a more comfortable and functional home. However, navigating the process of finding Read More » -

Choosing the Right Appliances for Your Kitchen Extension

January 15, 2024 By adminAdding a kitchen extension can provide invaluable extra space for storage, preparation, and cooking in your home. One of the most important decisions when planning your Read More » -

Create Your Own Oasis: The Ultimate Guide to Indoor Vertical Gardening

September 19, 2023 By adminVertical gardening is an inventive and space-efficient way to grow plants indoors, especially in small areas. It offers year-round access to fresh fruits, vegetables, flowers, herbs, Read More » -

Create the Ideal Environment for Your Indoor Growing System With These Expert Tips and Tricks

July 12, 2023 By adminIn recent years, indoor gardening has seen a significant surge in popularity. This trend is particularly noticeable amongst city dwellers who don’t have access to traditional Read More »

-

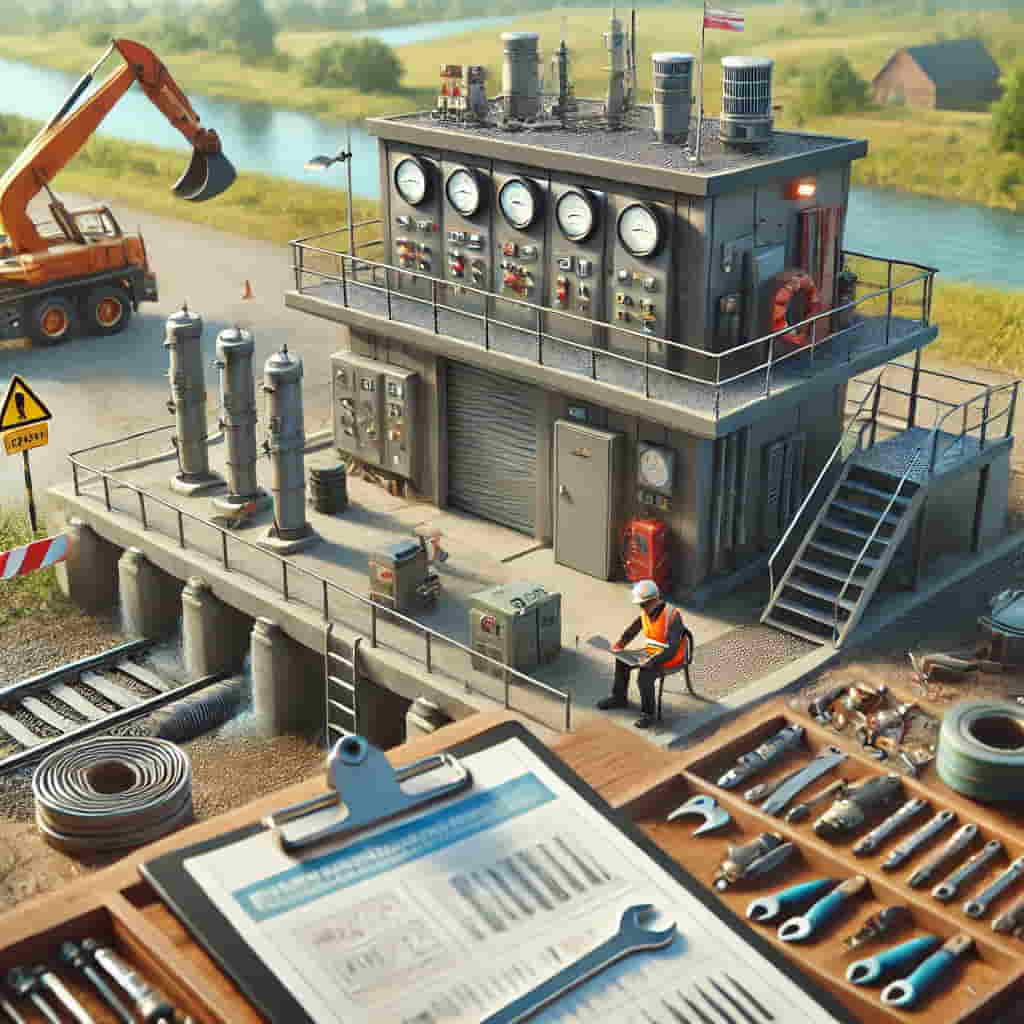

The Importance of Regular Maintenance for Lift Station Alarm Systems

Imagine you’re responsible for a bustling wastewater treatment plant. Every day, you oversee the smooth operation of lift stations, ensuring that wastewater is pumped efficiently through the treatment process. It’s not glamorous, but it’s vital. Yet, there’s one thing you never want to hear: silence.

In the world of lift stations, silence is not golden—it’s a red flag. It could mean that a pump has failed, a blockage has occurred, or a power outage has shut everything down. That’s where a lift station alarm comes in. These systems are your first line of defense, alerting you to issues before they escalate into full-blown crises. But here’s the kicker: just like the equipment they monitor, these alarm systems need regular maintenance. Ignore them at your peril.

Why Regular Maintenance of Lift Station Alarm Systems is Non-Negotiable

A lift station alarm is like the smoke detector of the wastewater world. It’s not something you think about daily, but when it does its job, it saves the day. Unfortunately, many operators fall into the trap of “set it and forget it” with their alarm systems. They assume that once installed, these systems will function flawlessly forever. But just as a smoke detector needs its batteries changed and its sensors tested, a lift station alarm requires regular upkeep to stay reliable.

The Anatomy of a Lift Station Alarm System

To understand why maintenance is crucial, it helps to know what makes up a lift station alarm system. Typically, these systems include:

- Sensors: These detect issues like high water levels, pump failures, or electrical faults.

- Control Panels: The brain of the operation, where the sensor data is processed.

- Communication Modules: These send alerts to operators via cellular, landline, or internet connections.

- Power Supply: Ensures the system runs even during power outages, often supported by battery backups.

Each component plays a vital role. If one fails, the whole system can be compromised. For instance, if a sensor gets clogged or damaged, it might not detect a high water level, leading to a flood. If the communication module isn’t working, you might not receive an alert about a pump failure until it’s too late. Regular maintenance checks ensure that all these components are functioning as they should.

The Perils of Neglecting Maintenance

Now, let’s talk about what happens when you neglect maintenance. It’s tempting to put off these tasks, especially when everything seems to be running smoothly. However, ignoring regular checks and tune-ups is a bit like skipping oil changes in your car. Sure, you might get away with it for a while, but sooner or later, you’ll be dealing with a costly and potentially catastrophic breakdown.

Silent Alarms: A Nightmare Scenario

One of the biggest risks of neglected maintenance is the “silent alarm”—a situation where the lift station alarm fails to alert you to an issue. This could happen for a variety of reasons: a sensor might be clogged with debris, the power supply could be depleted, or the communication module could be offline due to a network issue. Without regular testing, these problems can go unnoticed until disaster strikes.

Imagine the consequences: A sewer pump station alarm system fails to notify you that a pump has stopped working. By the time you realize something is wrong, wastewater has backed up, causing overflows that result in environmental violations, fines, and costly cleanup efforts. All of this could have been avoided with routine maintenance.

Recommended Maintenance Intervals: Protecting Your Operations

To keep your lift station alarm system in optimal condition, it’s essential to follow a regular maintenance schedule. Here’s a guideline to help you stay on track:

- Monthly Testing: Conduct a comprehensive test of the entire wastewater alarm system. This includes triggering the sensors to verify they activate the alarms and checking the communication system to confirm that alerts are sent and received as expected.

- Quarterly Inspections: Perform a thorough inspection of all sensors and control panels. Look for any signs of wear and tear, corrosion, or blockages, and address these issues promptly.

- Semi-Annual Battery Checks: Inspect and test your battery backups. Replace batteries if they show signs of weakness or if they are near the end of their service life to ensure they are ready when needed.

- Annual Professional Inspection: Engage a certified technician for a detailed system checkup. This inspection should include testing the calibration of sensors, reviewing system logs for any anomalies, and updating software or firmware.

Following these intervals not only ensures that your lift station alarm system is ready to respond when needed but also helps you comply with regulatory requirements, minimizing the risk of costly fines and environmental impacts.

Regulatory Compliance: Keeping Up with Standards

In the United States, wastewater treatment plants are subject to strict regulations that govern the operation and maintenance of lift station alarm systems. The Environmental Protection Agency (EPA) and local state agencies require regular monitoring and reporting to prevent environmental hazards. These regulations are designed to protect public health and the environment, ensuring that wastewater systems operate safely and efficiently.

Compliance isn’t just about avoiding penalties; it’s about safeguarding the community and environment from potential hazards like sewage overflows and groundwater contamination. By adhering to these regulations and maintaining your lift station alarm systems according to the guidelines, you demonstrate a commitment to environmental stewardship and public safety.

Learning from Experience: Real-World Consequences of Alarm Failures

To further emphasize the importance of regular maintenance, let’s consider a real-world example. In 2018, a wastewater treatment plant in the Midwest experienced a significant lift station failure due to a malfunctioning lift station alarm system. The sensors were clogged with debris, causing the system to miss a critical pump failure. As a result, untreated wastewater overflowed into a nearby river, leading to severe environmental damage and hefty fines for the plant.

This incident could have been prevented with regular maintenance checks and system upgrades. It serves as a stark reminder of the potential consequences of neglecting your lift station alarm system.

Conclusion: Peace of Mind Through Regular Maintenance

At the end of the day, maintaining your lift station alarm system isn’t just about avoiding problems—it’s about peace of mind. When you know your system is well-maintained, you can focus on the bigger picture, confident that your first line of defense is ready to alert you to any issues.

So, the next time you’re tempted to put off that maintenance check, remember: A well-maintained lift station alarm system is the best insurance you can have against the unexpected. After all, in the world of wastewater treatment, the only thing worse than a loud alarm is no alarm at all.